1. Scope of application: AC rated voltage 450 / 750V and below power, lighting, electrical equipment, instrumentation and telecommunications equipment connection and internal

power cord

power cord

Installation line.

2. Laying occasions and methods: indoor open laying, trench channel, wall or overhead laying in tunnel; outdoor overhead laying, laying through iron pipe or plastic pipe, laying of electrical equipment, instrument and radio device are all fixed laying; plastic sheathed power line can be directly buried in soil.

3. General requirements: economical and durable, simple structure.

4. Special requirements:

1) Outdoor laying, affected by sunlight, rain, freezing and other conditions, requires atmospheric resistance, especially sunlight aging resistance;

2) In use, it is easy to be damaged by external force or inflammable, and it is in contact with oil in many occasions. When threading the pipe, the power line is subject to large tension and may be scratched, so lubrication measures should be taken;

3) For internal use of electrical equipment, when the installation position is small, it should have certain flexibility, and the insulation wire core should have clear color separation, and should cooperate with the corresponding connector terminal and plug to make the connection convenient and reliable; for the occasions with anti electromagnetic requirements, shielding power line should be used;

4) The sheathed rubber power cord should be used for high ambient temperature, and heat-resistant rubber power cord should be used for special high-temperature occasions.

5. Structural composition

1. Conductor core: copper core is preferred when used for internal installation of power, lighting and electrical equipment, and tight pressed wire core is preferred for large cross-section conductor; class 1 or type 2 conductor structure is generally used for fixed installation.

2. Insulation: natural styrene butadiene rubber, polyvinyl chloride, polyethylene, nitrile polyvinyl chloride composite are generally used as insulation materials; heat resistant power line is made of PVC with temperature resistance of 90 ℃.

3. Sheath: there are five kinds of sheathing materials: PVC, cold resistant PVC, ant proof PVC, black PE, chloroprene rubber, etc.

Black polyethylene and chloroprene sheathed power lines should be selected for special cold resistance and outdoor overhead laying.

In the environment of external force, corrosion and humidity, the power cord with rubber or plastic sheath can be used.

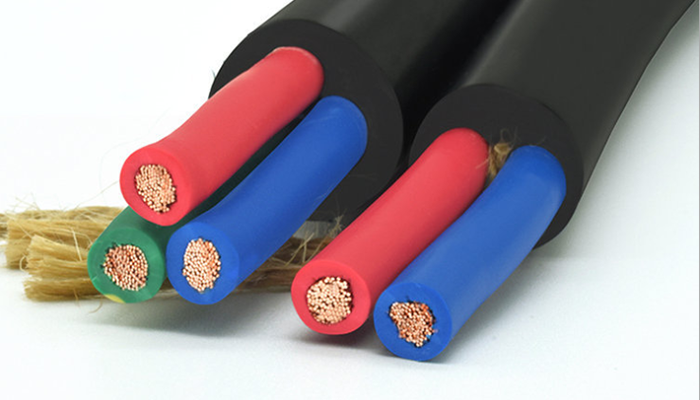

Rubber plastic soft power cord

1. Scope of application: it is mainly used for the connection of medium and light mobile appliances (household appliances, electric tools, etc.), instruments, power lighting; working electricity

power cord

power cord

The voltage is AC 750V and below, and most of them are AC 300C.

2. Because the product needs to move, bend and twist frequently, the power cord should be soft, stable in structure, not easy to kink, and have certain wear resistance; the rubber power cord with plastic sheath can be directly buried in the soil.

3. The grounding wire adopts yellow green double color wire, and other cores in rubber power line are not allowed to use yellow green wire core.

4. Braided rubber insulated cord or rubber insulated cord shall be used as power supply connecting wire of electric heating appliance.

5. The structure is simple and light.

6. Structure

1) Lead wire core: copper core, soft structure, stranded by multiple single strands; flexible conductor generally adopts class 5 or class 6 conductor structure.

2) Insulation: natural styrene butadiene rubber, polyvinyl chloride or soft polyethylene plastic are generally used as insulation materials.

3) The multiple of cable pitch is small.

4) The outer protective layer is woven with cotton yarn to avoid overheating and scalding the insulation layer.

5) In order to facilitate the use and simplify the production process, the three core balance structure is adopted, which can save production time and improve production efficiency.

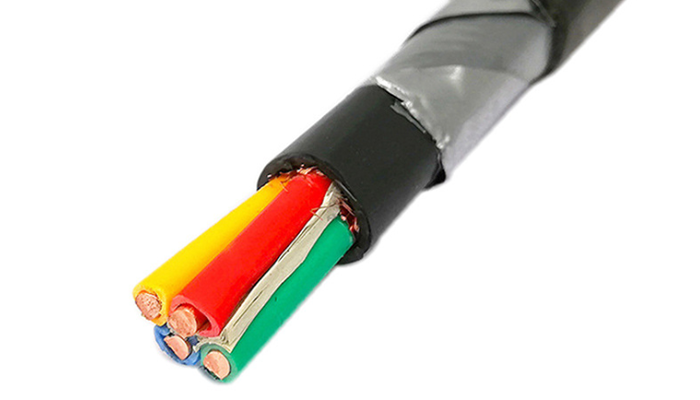

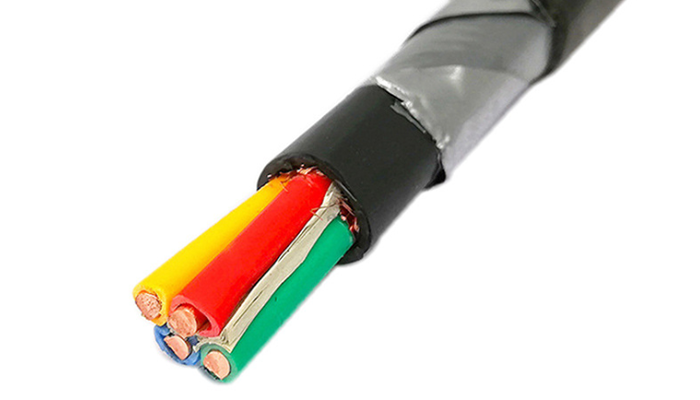

Shielded insulated power line

1. Performance requirements of shielded power line: basically the same as that of unshielded power line.

2. Due to the requirements of shielding (anti-interference performance) of the equipment, it is generally recommended to be used in medium level electromagnetic interference occasions; the rubber power line with plastic sheath can be directly buried in the soil.

3. The shielding layer should be able to have good contact with the connecting device or one end of the grounding, and the shielding layer should not be loosened, and not easy to be scratched by foreign objects.

4. Structure

1) Lead wire core: tin plating is allowed in some occasions;

2) The surface covering density of the shielding layer shall meet the standard or the user's requirements; the shielding layer shall be braided or wound with tinned copper wire; if the sheath shall be extruded outside the shield, the shielding shall be braided or wound with soft round copper wire.

3) In order to prevent the internal interference between the cores or pairs, the shielding structure of each core (or pair) can be produced.

Rubber plastic soft power cord

1. Scope of application: it is mainly used for the connection of medium and light mobile appliances (household appliances, electric tools, etc.), instruments, power lighting; working electricity

power cord

power cord

The voltage is AC 750V and below, and most of them are AC 300C.

2. Because the product needs to move, bend and twist frequently, the power cord should be soft, stable in structure, not easy to kink, and have certain wear resistance; the rubber power cord with plastic sheath can be directly buried in the soil.

3. The grounding wire adopts yellow green double color wire, and other cores in rubber power line are not allowed to use yellow green wire core.

4. Braided rubber insulated cord or rubber insulated cord shall be used as power supply connecting wire of electric heating appliance.

5. The structure is simple and light.

6. Structure

1) Lead wire core: copper core, soft structure, stranded by multiple single strands; flexible conductor generally adopts class 5 or class 6 conductor structure.

2) Insulation: natural styrene butadiene rubber, polyvinyl chloride or soft polyethylene plastic are generally used as insulation materials.

3) The multiple of cable pitch is small.

4) The outer protective layer is woven with cotton yarn to avoid overheating and scalding the insulation layer.

5) In order to facilitate the use and simplify the production process, the three core balance structure is adopted, which can save production time and improve production efficiency.

Shielded insulated power line

1. Performance requirements of shielded power line: basically the same as that of unshielded power line.

2. Due to the requirements of shielding (anti-interference performance) of the equipment, it is generally recommended to be used in medium level electromagnetic interference occasions; the rubber power line with plastic sheath can be directly buried in the soil.

3. The shielding layer should be able to have good contact with the connecting device or one end of the grounding, and the shielding layer should not be loosened, and not easy to be scratched by foreign objects.

4. Structure

1) Lead wire core: tin plating is allowed in some occasions;

2) The surface covering density of the shielding layer shall meet the standard or the user's requirements; the shielding layer shall be braided or wound with tinned copper wire; if the sheath shall be extruded outside the shield, the shielding shall be braided or wound with soft round copper wire.

3) In order to prevent the internal interference between the cores or pairs, the shielding structure of each core (or pair) can be produced.

Rubber plastic soft power cord

1. Scope of application: it is mainly used for the connection of medium and light mobile appliances (household appliances, electric tools, etc.), instruments, power lighting; working electricity

power cord

power cord

The voltage is AC 750V and below, and most of them are AC 300C.

2. Because the product needs to move, bend and twist frequently, the power cord should be soft, stable in structure, not easy to kink, and have certain wear resistance; the rubber power cord with plastic sheath can be directly buried in the soil.

3. The grounding wire adopts yellow green double color wire, and other cores in rubber power line are not allowed to use yellow green wire core.

4. Braided rubber insulated cord or rubber insulated cord shall be used as power supply connecting wire of electric heating appliance.

5. The structure is simple and light.

6. Structure

1) Lead wire core: copper core, soft structure, stranded by multiple single strands; flexible conductor generally adopts class 5 or class 6 conductor structure.

2) Insulation: natural styrene butadiene rubber, polyvinyl chloride or soft polyethylene plastic are generally used as insulation materials.

3) The multiple of cable pitch is small.

4) The outer protective layer is woven with cotton yarn to avoid overheating and scalding the insulation layer.

5) In order to facilitate the use and simplify the production process, the three core balance structure is adopted, which can save production time and improve production efficiency.

Shielded insulated power line

1. Performance requirements of shielded power line: basically the same as that of unshielded power line.

2. Due to the requirements of shielding (anti-interference performance) of the equipment, it is generally recommended to be used in medium level electromagnetic interference occasions; the rubber power line with plastic sheath can be directly buried in the soil.

3. The shielding layer should be able to have good contact with the connecting device or one end of the grounding, and the shielding layer should not be loosened, and not easy to be scratched by foreign objects.

4. Structure

1) Lead wire core: tin plating is allowed in some occasions;

2) The surface covering density of the shielding layer shall meet the standard or the user's requirements; the shielding layer shall be braided or wound with tinned copper wire; if the sheath shall be extruded outside the shield, the shielding shall be braided or wound with soft round copper wire.

3) In order to prevent the internal interference between the cores or pairs, the shielding structure of each core (or pair) can be produced.

Rubber plastic soft power cord

1. Scope of application: it is mainly used for the connection of medium and light mobile appliances (household appliances, electric tools, etc.), instruments, power lighting; working electricity

power cord

power cord

The voltage is AC 750V and below, and most of them are AC 300C.

2. Because the product needs to move, bend and twist frequently, the power cord should be soft, stable in structure, not easy to kink, and have certain wear resistance; the rubber power cord with plastic sheath can be directly buried in the soil.

3. The grounding wire adopts yellow green double color wire, and other cores in rubber power line are not allowed to use yellow green wire core.

4. Braided rubber insulated cord or rubber insulated cord shall be used as power supply connecting wire of electric heating appliance.

5. The structure is simple and light.

6. Structure

1) Lead wire core: copper core, soft structure, stranded by multiple single strands; flexible conductor generally adopts class 5 or class 6 conductor structure.

2) Insulation: natural styrene butadiene rubber, polyvinyl chloride or soft polyethylene plastic are generally used as insulation materials.

3) The multiple of cable pitch is small.

4) The outer protective layer is woven with cotton yarn to avoid overheating and scalding the insulation layer.

5) In order to facilitate the use and simplify the production process, the three core balance structure is adopted, which can save production time and improve production efficiency.

Shielded insulated power line

1. Performance requirements of shielded power line: basically the same as that of unshielded power line.

2. Due to the requirements of shielding (anti-interference performance) of the equipment, it is generally recommended to be used in medium level electromagnetic interference occasions; the rubber power line with plastic sheath can be directly buried in the soil.

3. The shielding layer should be able to have good contact with the connecting device or one end of the grounding, and the shielding layer should not be loosened, and not easy to be scratched by foreign objects.

4. Structure

1) Lead wire core: tin plating is allowed in some occasions;

2) The surface covering density of the shielding layer shall meet the standard or the user's requirements; the shielding layer shall be braided or wound with tinned copper wire; if the sheath shall be extruded outside the shield, the shielding shall be braided or wound with soft round copper wire.

3) In order to prevent the internal interference between the cores or pairs, the shielding structure of each core (or pair) can be produced.